Turntables and Slewing Rings

Our range of turntable ball bearings and slewing rings are used in many applications. Turntable bearings in the L range are suitable for use on light vehicles and axial load can be exceeded by 30 to 50% on the turntables of the N series. Turntable series HE and SO can be used on heavier vehicles with higher speeds. Suitable on agricultural trailers and semitrailers.

Our ball race series include both low profile ball race models and double row ball race models. Below is a list of ball bearing turntables and slewing rings products supplied by JOST Australia.

Optional central grease manifold available KLE0000200

Ball Bearing Turntable Series L and N

Description:

Ball bearing turntables.

Applications:

L-Series: up to 30km/h (18m.p.h)

- Farm carts

- Trailers

H-Series: > 30km/h (18m.p.h)

- Heavy farm carts

- Light truck trailers

Features:

- Slewing rings are supplied undrilled and primed in black for corrosion protection.

- The measurements are subject to our standard tolerances.

- For the turntables of the N series the load limits are only valid for operation on paved roads and under conditions prevailing in Europe.

- The axial load can be exceeded by 30 to 50% on the turntables of the N series if the speed is below 30 km/h (18 m.p.h.).

Ball Bearing Turntable Series HE and SO

Description:

Ball bearing turntables.

Applications:

For speeds up to 105km/h (65m.p.h)

- Drawbar Trailers

- Special Trailers

Features:

- Ball bearing turntables are supplied undrilled.

*drilled and primed in black for corrosion protection. - The measurements are subject to our standard tolerances.

- The above axial loads are applicable if the slewing ring is mounted to the front axle of the trailer with three/four axles at speeds of up to 105 km/h (65 mph).

- They can be exceeded by 10% for full trailers with two axles.

- In case of speeds below 30 km/h (18 mph) the axial loads can be exceeded by 20%.

- If required axial loads exceed the data permitted for turntables of series HE/SO, please ask for slewing rings of series KDL 900, which allow axial loads up to 250 kN.

- In case of use above the steered axle and above the fifth wheel on semi-trailers with rear axle steering please enquire as to the load data giving details of the vehicle.

- The load limits are only valid for operation on paved roads and under conditions prevailing in Europe.

Low Profile Ballrace KDL 900/6W Series

Description:

Low profile ballrace models.

Applications:

- General Freight

- Fridge Vans

- Stock Crate

- Tippers

Features:

- Slewing rings are supplied primed for corrosion protection.

- Material C45.

- Ball race hardened.

- 8 conical lubrication nipples AM 8 x 1 according to DIN 71412.

The above axial loads are applicable if the slewing ring is mounted to the front axle of a trailer at speeds of up to 105 km/h (65 m.p.h.). If it is to be used in self steering systems or above a fifth wheel please contact us for the maximum permissible loads by submitting construction data.

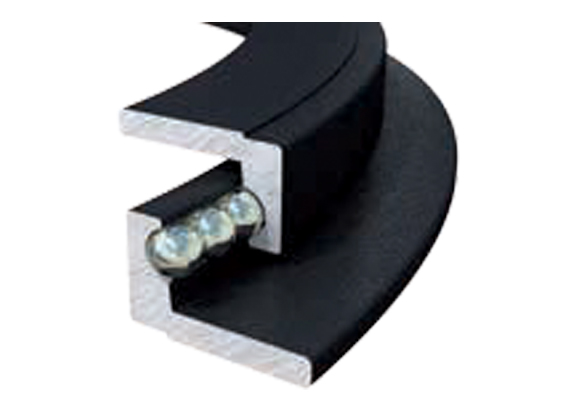

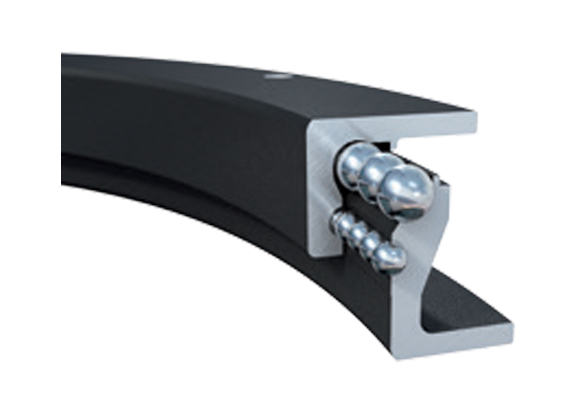

Double Row Ballrace KLK DR Series

Description:

Double row ballrace.

Applications:

- Drilled or Undrilled

- 1000, 1100, 1200 widths available

- Tankers

- Tippers

- Dog Trailers

- Low Loader Trailers

Features:

- JOST turntables are equipped with supporting and retaining ball races between the upper and lower rings.

- The axial forces on the turntables are accepted vertically via the large supporting ball bearings.

- The horizontal tensile and compressive forces incurred are accepted by the smaller retaining ball bearings.

- The moment forces resulting from braking and centrifugal forces, are mutually accepted by the supporting and retaining ball bearings.

- The retaining ball bearings connect the upper and lower turntable rings.

- The design principle ensures maximum reliability because the active axial and radial forces are distributed between the two ball races of JOST turntables.

- The ball races are permanently protected against dirt and dust by a multi-lip seal.